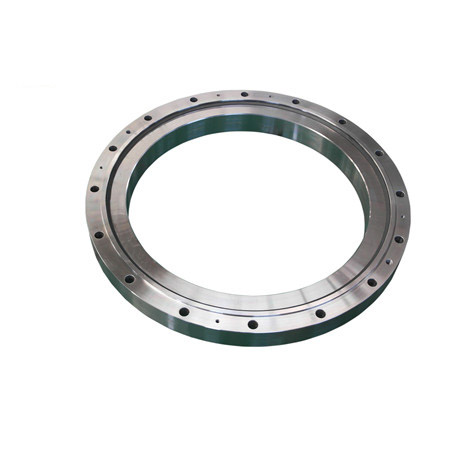

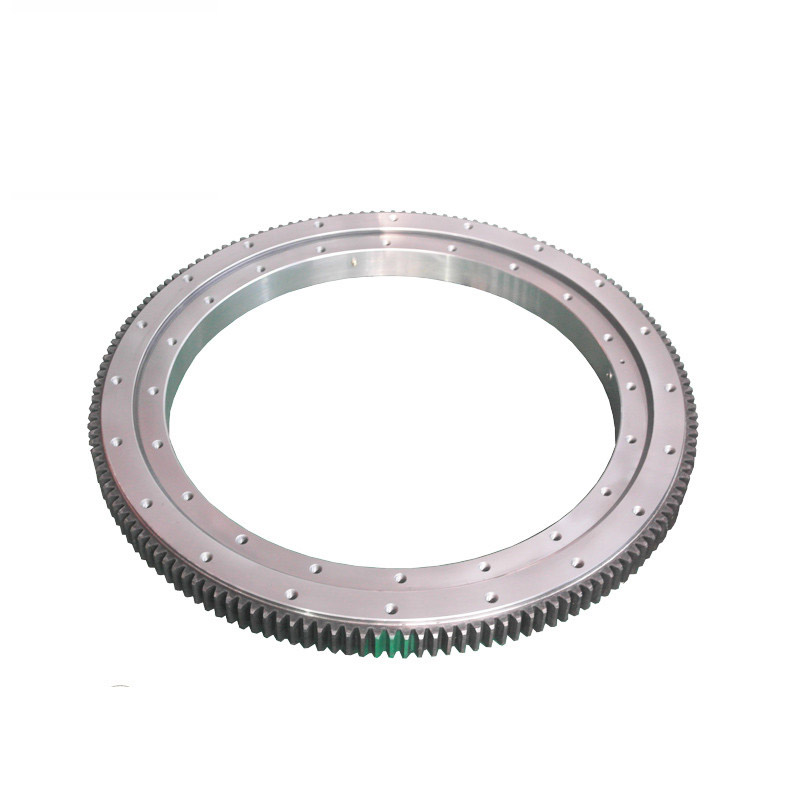

1. The installation method is different. The slewing bearing is not sleeved on the mandrel and installed in the bearing box like an ordinary bearing, but is fixed on the upper and lower supports by screws.

2. Generally, the slewing bearing must bear several loads, not only the axial force and radial force, but also the large overturning moment. Therefore, a set of slewing bearings often plays the role of several sets of ordinary rolling bearings.

3. The running speed of the slewing bearing is low, usually below 50 rpm. In many cases, the slewing bearing does not operate continuously, but only rotates back and forth within an angle, which is equivalent to the so-called "swing bearing".

4. The size of the slewing bearing is large, and its diameter is usually 0.4-10 meters, and some are as large as 40 meters.

5. Generally, the slewing bearing is provided with a ring gear for rotational driving and a sealing device for dust prevention.

6. In terms of materials and heat treatment manufacturing processes, slewing bearings and rolling bearings are very different.