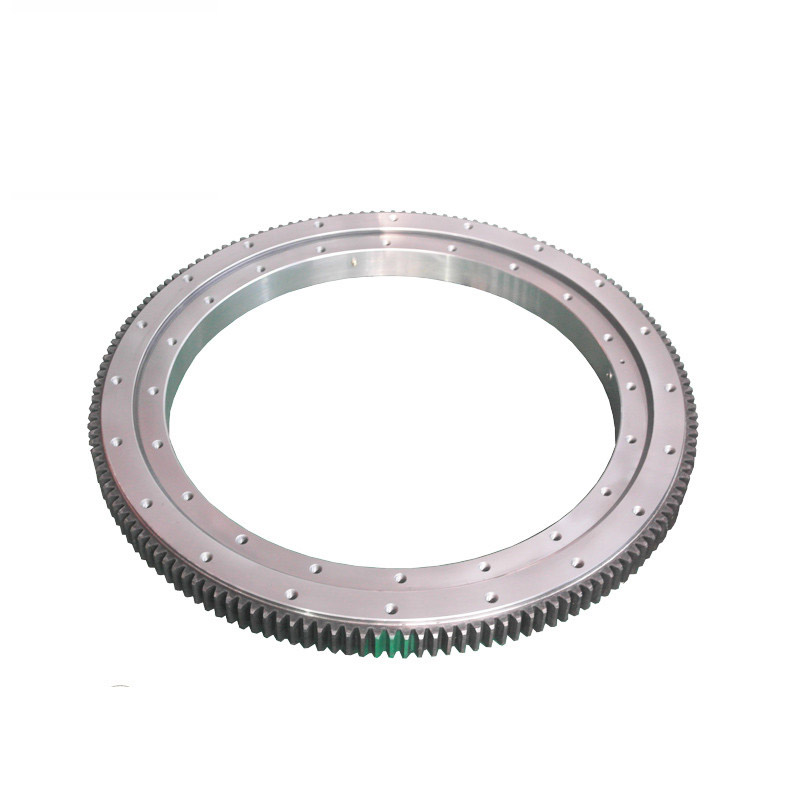

The repair method is: first remove the rollers or steel balls in the slewing bearing to separate the inner and outer rings; then clean the raceway with gasoline; then use a polisher to carefully and carefully produce the area around the needle stripping area of the Microsoft Corporation of the United States. The hardened layer of the crack is removed, and the bottom of the peeled layer is smoothed; the welding path of the raceway needs to be preheated with a welding torch, and the medium carbon steel electrode is used for welding. The welding layer should be slightly higher than the surface of the raceway 1- 2mm; if the delamination is deep or the area is large, the welding should be carried out in layers, not to cause the base metal temperature to be too high and cause deformation; this avoids welding cracks caused by rapid cooling, and insulation measures should be taken immediately after welding to make him gradually cool down.